These cables are manufactured as per customers specification. It acts as a link between the transformer and the spot welding gun for current transfer. Flexible braided wire is used to manufacture the conductor for efficient current transfer. It is available in about 300 MCM to 1000 MCM, which varies as per the requirements of the customers.

Specification

| Item | Specification | ||||||||

| 300 MCM (2x150 Sq.mm.) | 400 MCM (2x200 Sq.mm.) | 500 MCM (2x250 Sq.mm.) | |||||||

| 2.0 m | 2.4 m | 3.0 m | 2.0 m | 2.4 m | 3.0 m | 2.0 m | 2.4 m | 3.0 m | |

| Resistance (μΩ) * | 460 | 550 | 680 | 330 | 400 | 495 | 265 | 320 | 400 |

| Reactance (μΩ) ** | 68 | 81 | 90 | 45 | 57 | 71 | 33 | 44 | 57 |

| Impedance (μΩ) ** | 465±10 | 556±10 | 686±10 | 333±15 | 404±15 | 500±15 | 267±20 | 323±20 | 404±20 |

| Power Factor | ≈0.99 | ||||||||

| Breakdown Pressure | 8 kg/cm2 | ||||||||

| Cooling Water Rate | 6 Liter/min | ||||||||

| Outer Diameter (mm) | 52 mm | 56 mm | 63 mm | ||||||

Features / Highlights

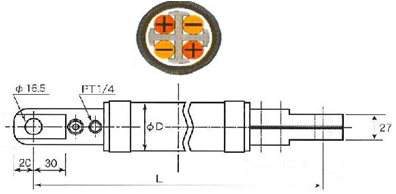

Unique “X-shape” separator maintains strand positioning and equally distributed cooling water flow.

State-of-the-art 4-wire design to minimize current loss, reduced CO2 emission.

Electrolytic tough pitch annealed, bare copper wire, 28 AWG, herringbone rope construction for greater flexibility and reduced wear point.

High temperature internal restraining collars to minimize stress in the bending area.

Lowest reactance of the class to engage lower primary power demand

No noticeable pulsation due to low magnetic kicking.

Improved flexibility, smaller bend radii comparing to previous model.

Reduced operator fatigue, higher productivity.

All customized length is available upon request.

Technical Specifications Of Kickless Cable (300 Mcm)

1. Test Pressure (water): 6.0 kgs./ cm sq. minimum., 10.0 kgs./cm. sq. maximum

2. Conductor : Electrolytic Copper (99.9% Pure)

3. Rubber hose : As per IS 55821-1986- Cured type.

4. No. of spots : 10 Lacks per cable.

5. Polarity : Alternate

6. Water flow : 6.0 Lit/min at 6 kgf/cm sq.

7. Cable Terminal : As per customer design.

8. Temperature : Withstands up to 50 Degree Centigrade

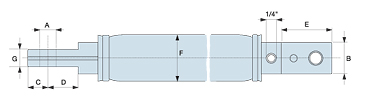

How To Order:

| MCM | A | B | C | D | E | F | G |

| 300 MCM (2x150) | 16.5 | 36 | 20 | 30 | 50 | 50 | 28 |

| 400 MCM (2x200) | 16.5 | 40 | 20 | 30 | 50 | 55 | 28 |

Terminals :

1. Machined from high conductivity electrolytic copper bar stock. However can be supplied in Cr Cu at extra cost.

2. Assembled with 1/4 '' bolt.

3. Separated by high quality insulating material.

4. Two parts chemical sealant - adhesive between terminals surface & gasket.

5. Large unobstructed water passage.

6. All terminals cross-section are as per MCM/Sq.mm rating of cable.

Wire Construction :

1. Wires are terminated in crimped joint against the inner surface of the terminal. Lateral surfaces are brazed to the terminal.

Note : This unique crimped joint also ensures a perfect joint compared to the other cables screwing & brazing pattern.

2. Wires cannot melt out during brief overloads.

3. These wires are again crimped in exclusive male & female pattern to position the wires to achieve the best alternate polarity design.

Strain Relief Behind Terminals:

Resilient, high temperature nylon strain relief collar located at rear of terminals. Rubber tubing around individual wire ropes at transition point into swaged connector tubes. External collar & individual rope tubing conjunctively distribute wire bending stresses over entire transitional area.

Flexible Hose Cover :

This is made of heat resistant on the inner surface & abrasion resistant on its outer surface.

Water Flow :

Cooling water is passed at the rate of 6 Lit/min at the pressure of 6 kg/cm2 & the pressure drop does not exceeds 0.7 kgf/cm2.

Water Pressure :

The cable is tested at a pressure of 6Kpl/cm2 (KSC), to ensure then there is no leakage or hose damage